Hydrogen technology

Hydrogen technology: A new energy vector for the society of the future. HEF studies and understands surface phenomena relating to hydrogen manufacturing, transport, storage, and hydrogen energy technologies such as electrolysis, compression, fuel cells, and hydrogen engines.

Contact our expertsDid you know?

In the context of decarbonizing our societies, hydrogen is one of the solutions considered for the future of energy. A research topic for several decades, the utilization of hydrogen as an “energy vector” (in other words, it must first be produced and stored before it can be used) could play a significant role in the energy transition, with impetus from both the industrial sector and the mobility sector.

It is available in abundance and its combustion is CO2-free. The hydrogen cycle can be divided into several categories: production, storage, transport, and use in various sectors.

HEF addresses the environmental issues by diversifying into markets linked to decarbonized energy, such as hydrogen: from upstream via hydrogen production to the use of hydrogen for electric or thermal mobility.

HEF’s objective is to make robust, sustainable, and economically competitive solutions available from 2025, with a view towards mass deployment by the year 2030.

The fuel cell principle is the reverse of the electrolysis principle. The chemical reaction triggered by the confluence of dihydrogen and dioxygen produces water, a little heat, but above all electricity, which can then be used for almost all applications.

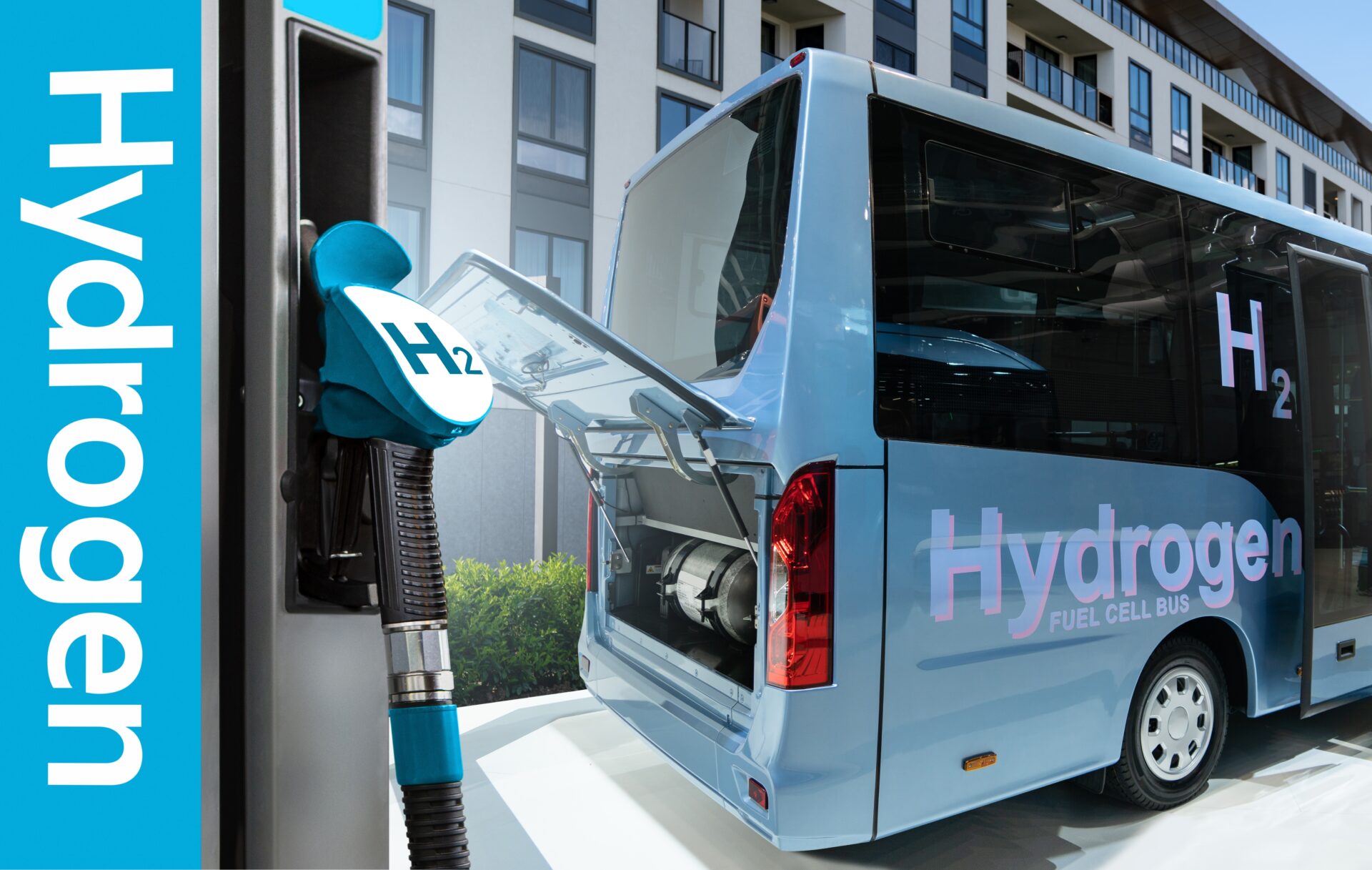

For example, today, fuel cells are used in the mobility sector to power new types of electric vehicles (referred to as “hydrogen fuel cell vehicles”).

Other means of transport can also benefit from hydrogen technology, for example, buses, trains or vehicles referred to as “intensive use” vehicles, such as taxis, captive fleets, utility vehicles, electric forklifts. For example, charging hydrogen forklifts is much faster (several minutes) compared to the 8 hours required to charge most electric forklifts with classic batteries.

Hydrogen has a very significant energy density (1 kg of hydrogen contains as much energy as 3 to 4 kg of gasoline). Its density is quite low in the natural gaseous state. Consequently, it must be extracted and compressed before it can be used.

There are two main methods for recovering this energy:

– In thermal form via the combustion of hydrogen with oxygen (combustion where the residue is water only; this is how the Vulcan engine of the European Ariane launcher works)

– In electrical from by using fuel cells (also referred to as hydrogen batteries).

Learn about our cutting-edge surface coatings and increase the performance of your fuel cells

HEF technologies and innovative PVD coatings improve and/or create new surface properties of bipolar plates, which are essential fuel cell components. Our hydrogen innovation technologies even improve the corrosion performance of bipolar plates in harsh environments (temperature, acidity, etc.).

HEF develops unique and resistant carbon coatings for metal bipolar plates. These plates are key components of proton exchange membrane fuel cells (PEMFCs).

Our coatings protect parts from corrosion, ensure optimal electric conductivity over operating times of several thousand hours, and emit low levels of contaminants (barrier effect).

High-performance coating solutions for electrolyzers

Before hydrogen can be used, it must first be produced.

Today, 95% of dihydrogen is produced by “steam reforming” of fossil fuels. This chemical reaction breaks down the hydrocarbon molecules in the presence of steam, heat, and a catalyst to release hydrogen. However, the disadvantage of this method is that it produces CO2.

Hydrogen can also be produced by electrolysis using water and electricity. Here, the principle is to split the water molecule into separate hydrogen and oxygen atoms. Even if this technique does the opposite of the fuel cell, the technology that enables such electrolysis is quite similar to that of the fuel cell. Namely “stacks” of large-dimension electrochemical monocells, connected in series, will make it possible to obtain hydrogen from water.

Since energy density depends on the surface of the elements, here, HEF also brings in our expertise in concept, creation, and design with surface quality control that goes down to tens of nanometers.

Each cell of an electrolyzer contains porous transport layers (PTLs) and the bipolar separator plates that play an essential role in flux distribution and electric current conduction. However, these plates operate in a corrosive environment.

Innovative PVD coatings and PVD-PECVD surface treatment technology developed by HEF play a key role in optimizing the performance of these surface treatments and ensuring their durability while reducing the quantities of precious metals used to the absolute minimum.