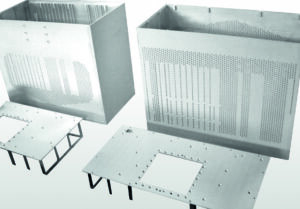

HEF technologies are utilized in virtually every business sector that is involved, either directly or indirectly, with surface design or surface protection. This means that our surface treatment know-how is relevant for a broad range of industries, such as the aerospace, power generation, civil engineering, automotive, defense, and even consumer goods sectors.

This privileged position is built on four major advantages:

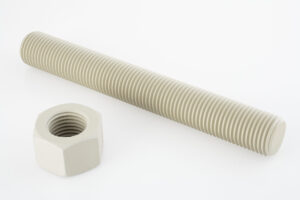

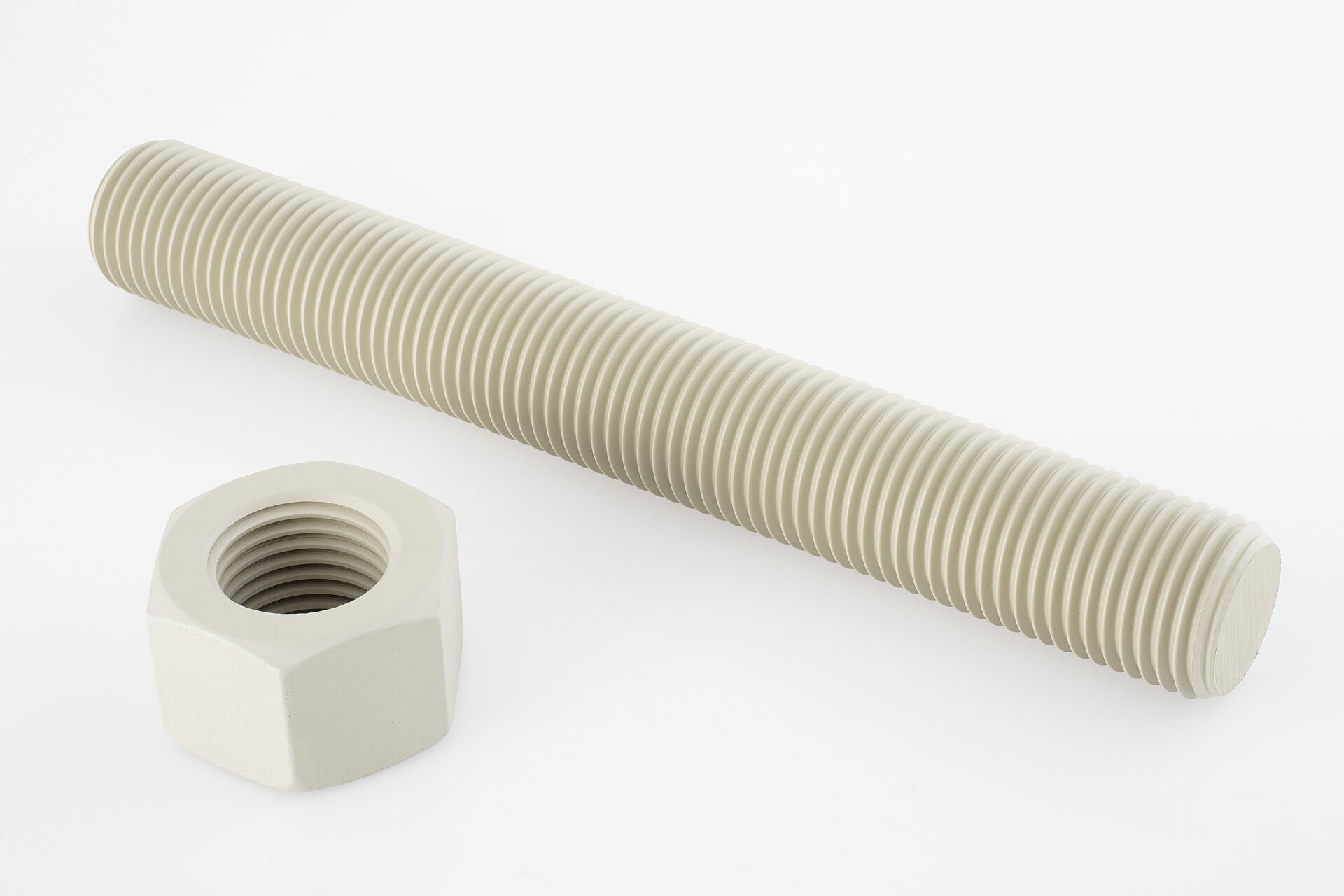

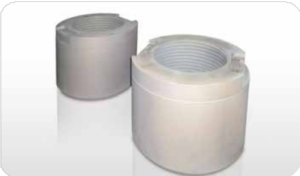

- • Our range of processes can be applied on most materials (steel, cast-iron, light alloys or copper alloys, ceramic, glass, polymer, etc.).

• Our surface treatment solutions are adapted to all functions: mechanical, optical, electrical, etc.

• Our ability to combine multiple treatments and/or technologies allows us to create a new surface function that appropriately meets a specific need.

• Our capacity to adapt technologies to a given environment have been proven in other industries.