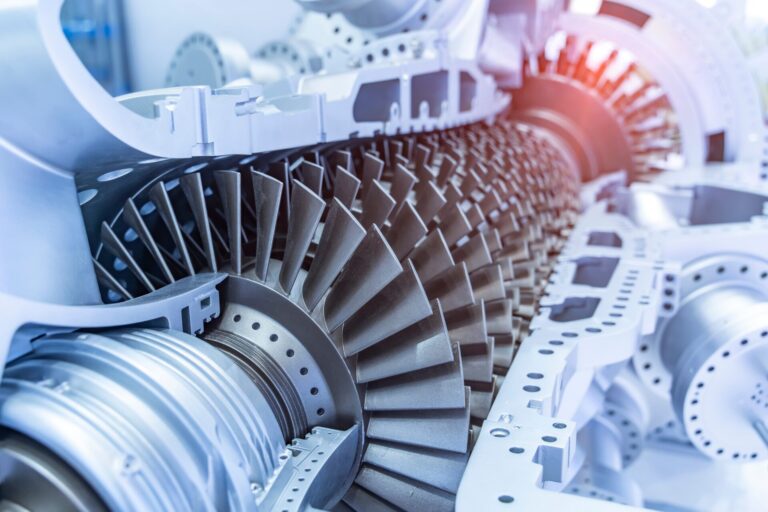

Resistance to adhesion and friction wear are crucial for technical aeronautic components.

At HEF, our our aerospace surface treatments include CLIN™ liquid nitriding technology which is applied on landing gear components, flight control actuators, and even cockpit door latches. CLIN™ treatments increase the resistance of these parts to seizing and fatigue, and on steel, they increase protection against corrosion. Given their robustness, parts treated with CLIN™ offer better characteristics than can usually be obtained through gas/plasma nitriding.

To solve problems involving wear or seizing that impact or cause component defects, HEF’s surface treatments for the aerospace industry also include a hard coating with long-term effectiveness. Our CERTESS® NITRO coating reduces major risks in the high-safety sector through a low coefficient of friction, good functional stability, and increased wear resistance even at extremely high temperatures.

Providing excellent tribological coating, ceramic coatings offer versatile performance because they protect against seizing, offer uniform coverage, and provide better temperature resistance.