For millennia, humankind has harnessed the power of water to power mills and build dams. Today, this natural resource has become one of the world’s primary sources of clean electricity.

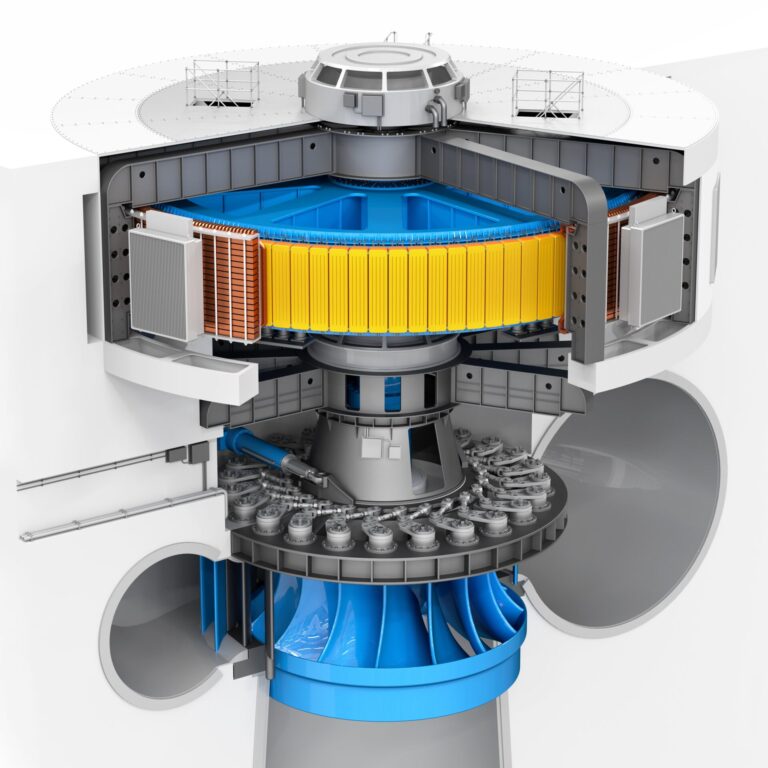

Hydraulics exploits the energy potential of water by making it pass through turbines, thus converting its kinetic energy into electricity.

The HEF Group’s composite self-lubricating hydraulic solutions for electricity production have been used for more than 20 years in power plants throughout the entire world, where they replace copper alloy bushings on:

- FRANCIS, KAPLAN, PELTON turbines on the wicket gates, winnowing ring, connecting rod, the KAPLAN blade orientation, injector guidance, etc.

- Segment valves, gate valves, butterfly valves, faucet valves, spherical valves, etc.

- Weirs

Why contractors rely on HEF:

- Self-lubricating solution: no water pollution

- Low coefficient of friction > less energy required to move parts

- Six-fold weight reduction compared to copper alloy bushings; facilitated maintenance

- Increased service life

- Negligible water absorption

- 20+ years’ expertise and industry experience

- Competitive prices

- Short lead times

- Dimensioning up to 2 m in diameter