Functionalized powders

For over 20 years, HEF has specialized in the functionalization of high value-added powders. We develop functional powders based on your specifications for your applications in additive manufacturing, sintering, Cold Spray… Our multi-material powders are obtained through dry processes (PVD, OMCVD, thermochemistry…) or wet processes (electroless, sol-gel…). We offer complete or partial functionalizations, or inclusions within the core of your base powder.

Contact our experts

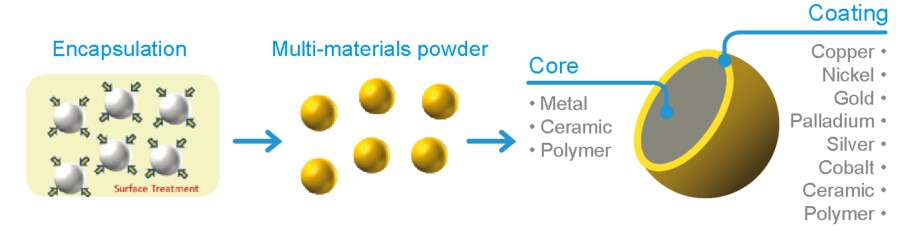

Choose multi-material functional powders!

HEF develops your desired functionalities using multi-material functional powders. Improve your surface properties such as hardness, lubrication, conductivity, diffusion barrier role, corrosion resistance, or wettability.

The use of functionalized powder for the manufacturing of parts allows for the creation of composites with unique and homogeneous microstructures.

HEF designs functional powders through surface modification (coating) or core treatment of a base powder (support powder), using complex technologies such as fluidized bed processing or mechanical synthesis.

Depending on the specifications of your requirements, we offer different configurations of base powders / coatings:

- metal/metal,

- ceramic/metal, metal/polymer,

- Single-layer or multi-layer functionalization.

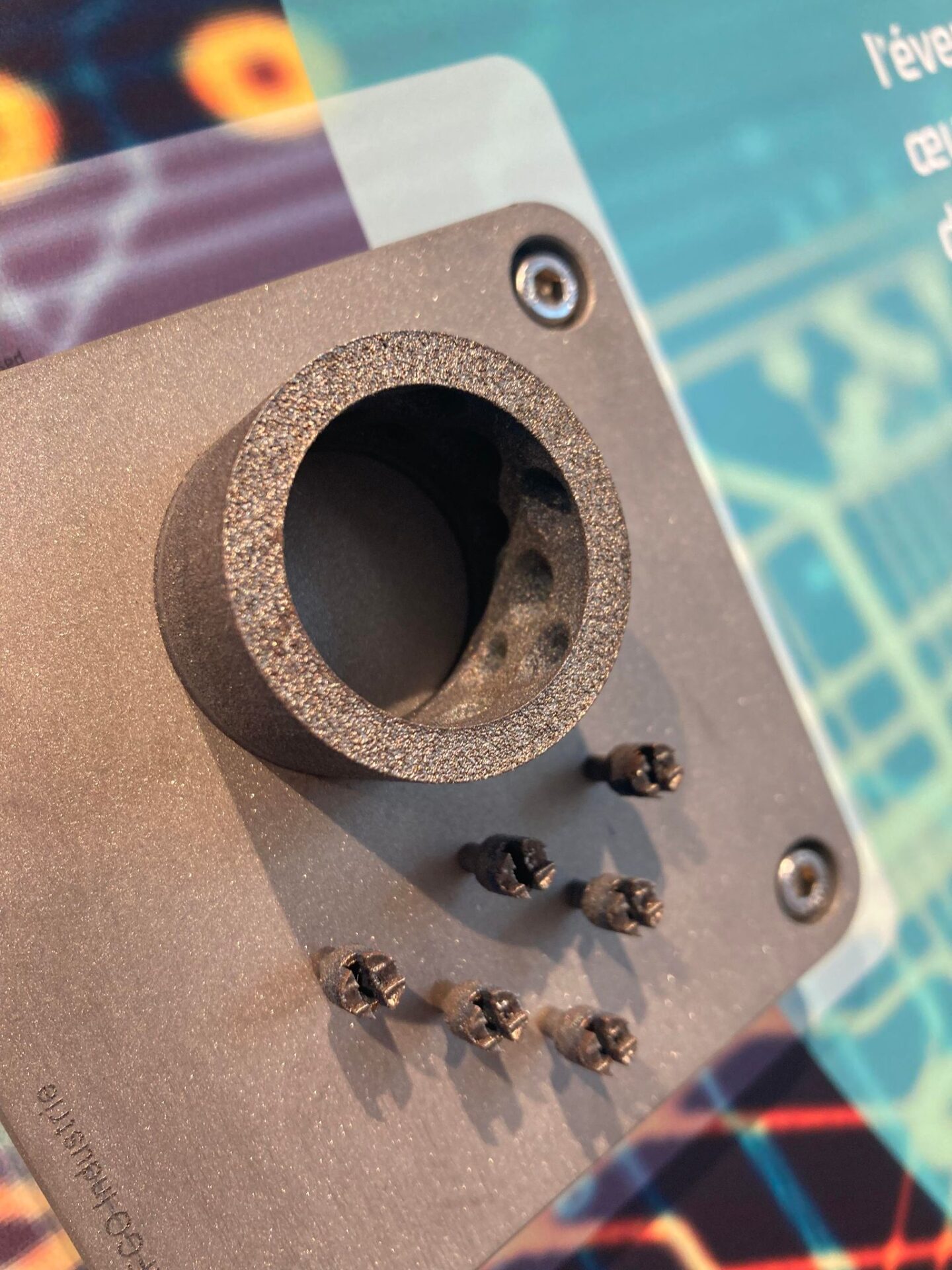

We can produce any powder morphology (see visual on the right).

Custom specifications to meet your needs

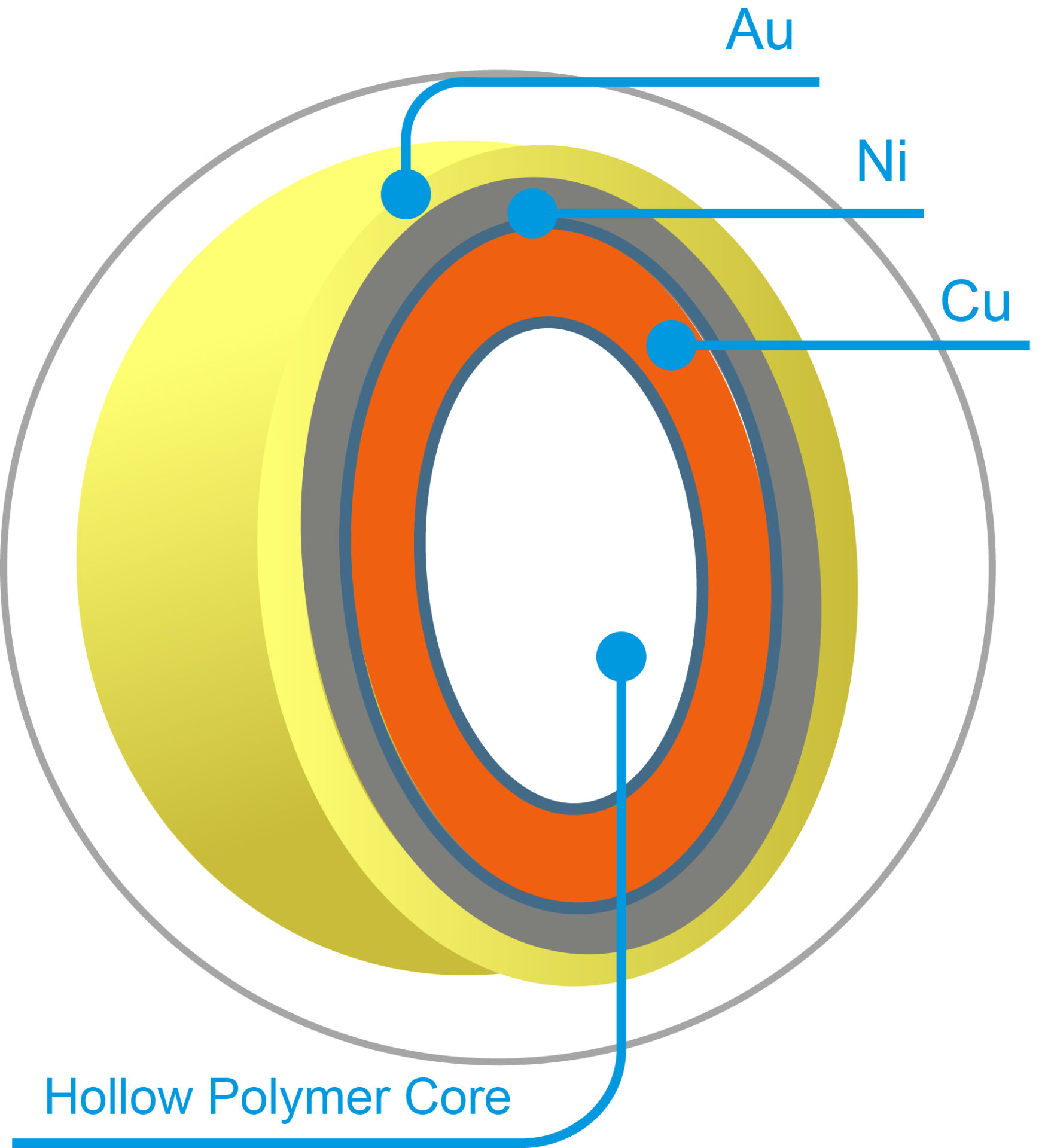

Polymer core solder balls.

HEF has developed polymer-core solder balls, thanks to a collaborative project initiated by Thales .

These solder balls help improve the life of electrical contacts when assembling BGAs on a printed circuit board.

- Alternative to traditional lead solder balls

- Reduced thermomechanical stress

- Improved reliability and reparability

- Compatible with solder reflow according to IPC-J-STD-001

- Miniaturization

- Flexible design with different coatings

- Controlled stand-off height (+/-5%)

Conception 3D flexible

Polymer-core solder balls are a high-performance solution to the usual technical problems. Key benefits :

- Controlled shrinkage height (+/-5%) to guarantee PCB flatness.

- High thermomechanical resistance compared to other solder ball solutions.

- Improved component lifecycle by 40%.

- Compatible with solder reflow process and solder paste.

- Common problems with electrical components :

- Temperature variation due to operating conditions under components, resulting in PCB variation and uncontrolled shrinkage height = component failure.

- Appearance of cracks on the solder ball due to thermomechanical stresses.

Diameter range of our solder balls :

From 280 microns to 800 microns.

Our markets

Our main markets are: aerospace and space, automotive, rail, naval, defense, luxury, and medical.

On a daily basis, we work on the development and production of innovative products that meet the most demanding specifications of our clients.

Custom-made technical powder coatings

HEF develops your future thermosetting powders.

We apply highly specialized powder coatings that meet the most demanding specifications.

All our powders are developed in accordance with REACH regulations and are applied by fluidized bed or spraying.

Each powder coating is developed based on the desired functional properties.

Powder coatings represent a sustainable and responsible alternative to liquid paints and contain no volatile organic compounds.

Coating types :

- Electrical conductivity

- Thermal conductivity

- Dielectric

- Fireproof

- Protection against corrosion

- Decorative coating

- Highly chemical-resistant coating

- Self-lubricating

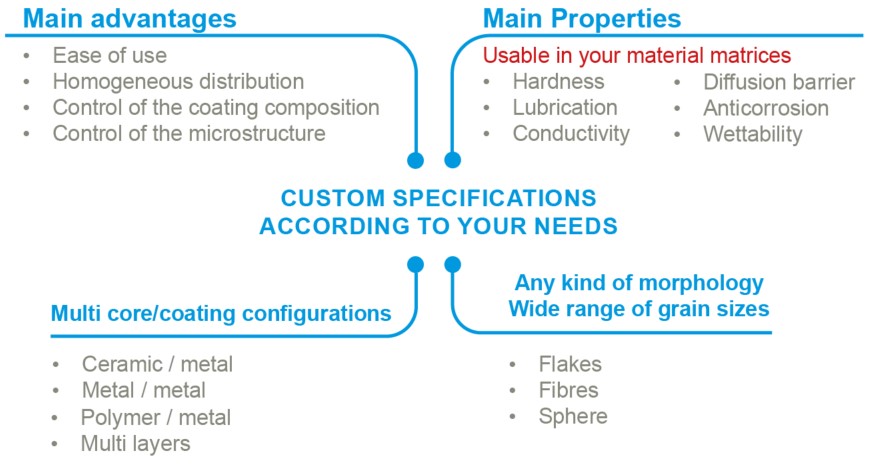

Industrial players are increasingly turning to additive manufacturing technologies, which currently have a very limited range of powders available. HEF provides real diversity in the selection of raw materials and expands their range by offering custom-made multimaterial powders (metal/metal, metal/ceramic, metal or ceramic/polymer) tailored to the chosen application technologies.

Conclusion

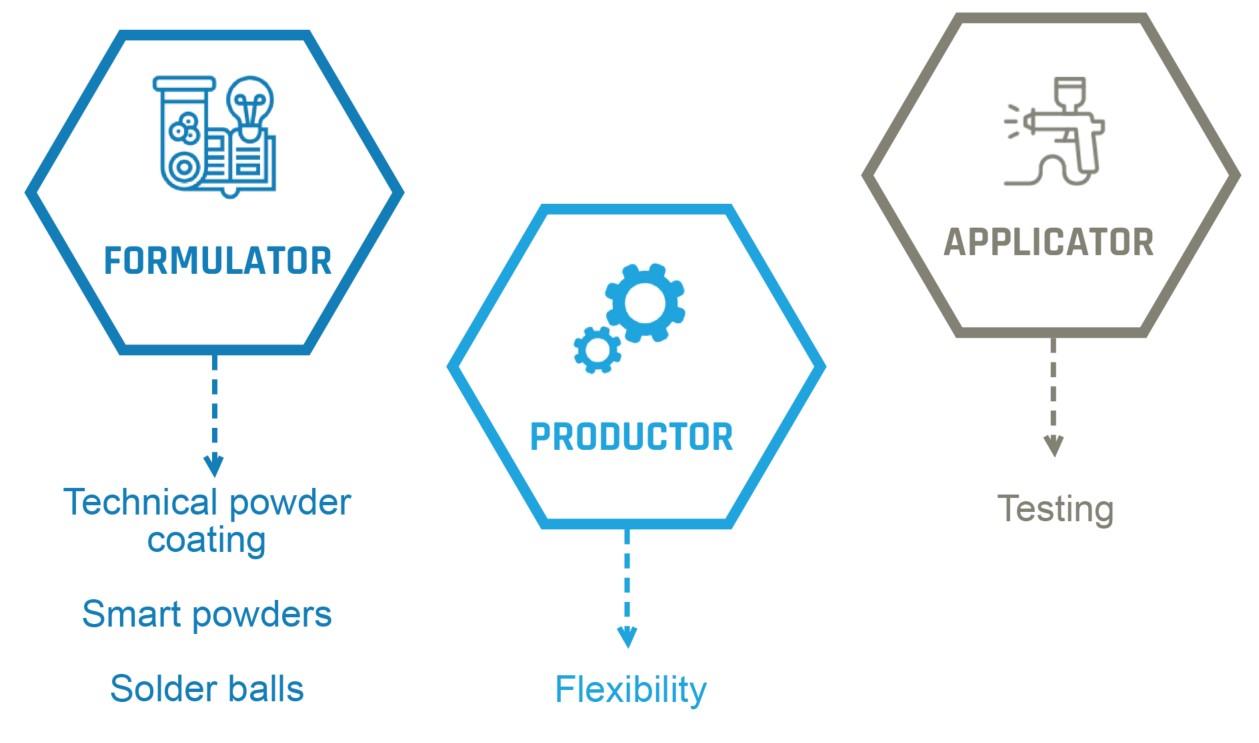

De manière totalement intégrée,

HEF propose la formulation, la fabrication et la mise en œuvre des poudres pour une offre de service complète.