The femtosecond laser is an ultrashort pulse laser (1 femtosecond is equivalent to 10-¹⁵ seconds) where the photon travels only the thickness of a hair, i.e. several tens of micrometers. This unique property makes it possible to sublime the material, while minimizing thermal effects, and doing this for all materials, from the hardest to the most active. We can modify the surface in dimensions ranging from microns to nanometers. High-power femtosecond lasers have been used in laboratories for over 20 years, and they are now ready for industrial production.

HEF innovates to industrialize a glass cutting process

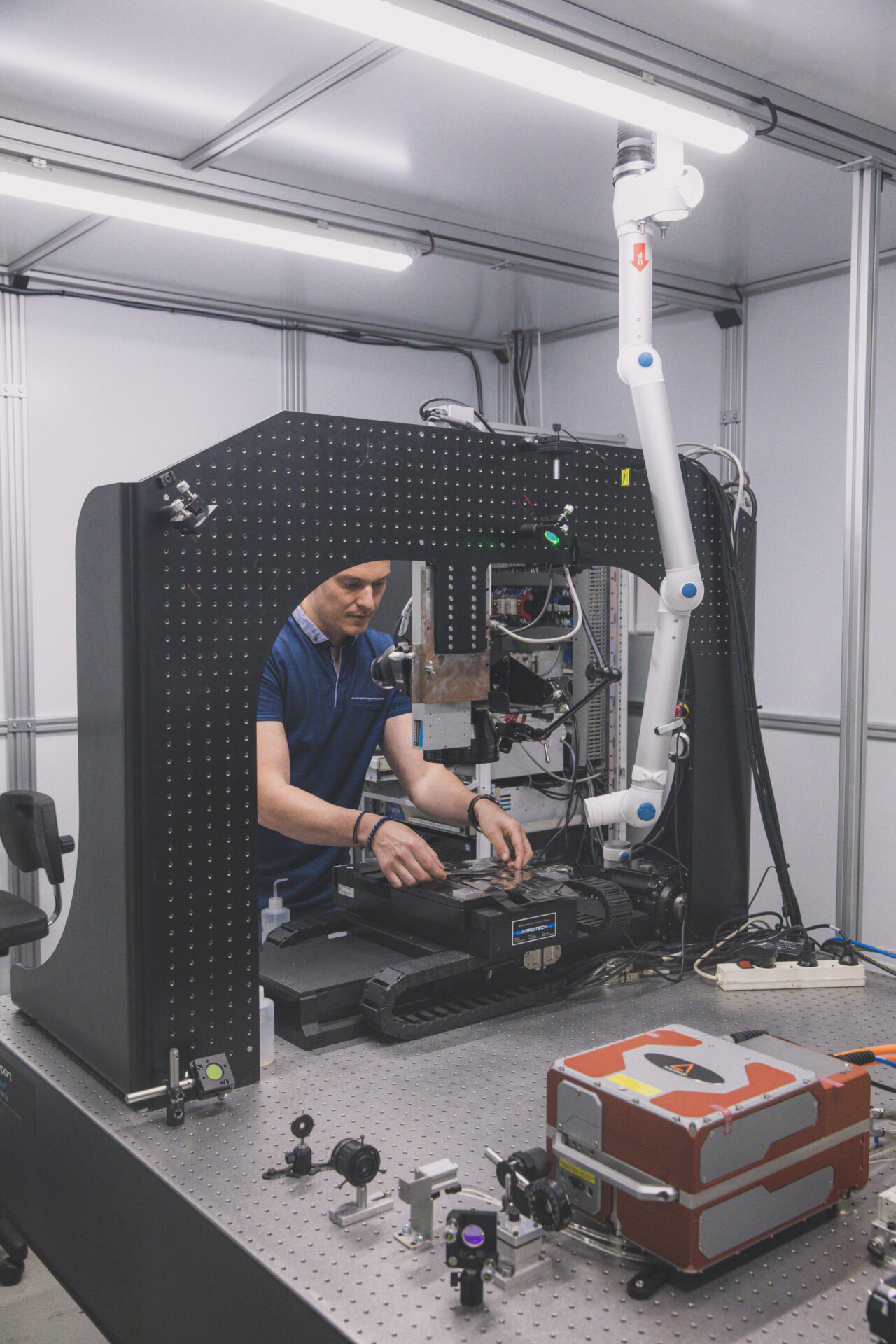

HEF, has invested in femtosecond laser surface treatment for over 15 years.

With the GLACIER project, HEF meets the needs of markets requiring photonic and optical components for electronics, display screens, semiconductors, optical solutions for transport (autonomous vehicles), and medical devices (diagnostics).

HEF wants to provide technical and economic solutions for industrial implementation of this laser, as it offers new solutions for texturing, engraving, cutting, drilling, marking, and micromachining of all materials. Its unique properties are getting more and more recognition, with a wide range of applications in all industrial sectors.