Tribology: The science at the heart of mastering mechanical system efficiency and durability

Tribology is the science that studies the phenomena that occur when two materials are in contact. In particular, tribology studies the friction and wear mechanisms in the presence or absence of lubrication. With regard to fields of application, it is impossible to provide a comprehensive list. The areas potentially impacted by tribology are vast in number and varied in requirements. They range from aerospace to medical and include transport, civil engineering, heavy industry, and even the tools of everyday life.

Contact our experts

Did you know?

There are very few mechanical systems where friction does not exist.

Even the International Space Station (ISS), which orbits in space 400 km above the Earth, is subject to very slight friction from the few residual molecules in the upper atmosphere. However, this slight friction requires the ISS to either expend fuel on a regular basis to elevate its orbit, or risk falling back down to Earth.

While the reduction of friction and wear in tribology is often sought to ensure the efficiency, durability, and even operational safety of a given system, friction need not always be avoided. As a matter of fact, without this phenomenon, it would not be possible, for example, to hold an object in our hand, build a pyramid, or fly a plane.

This friction is also often the cause of wear on mechanical parts that roll or slide over each other. While appropriate lubrication slows down the phenomenon, it never completely eliminates it.

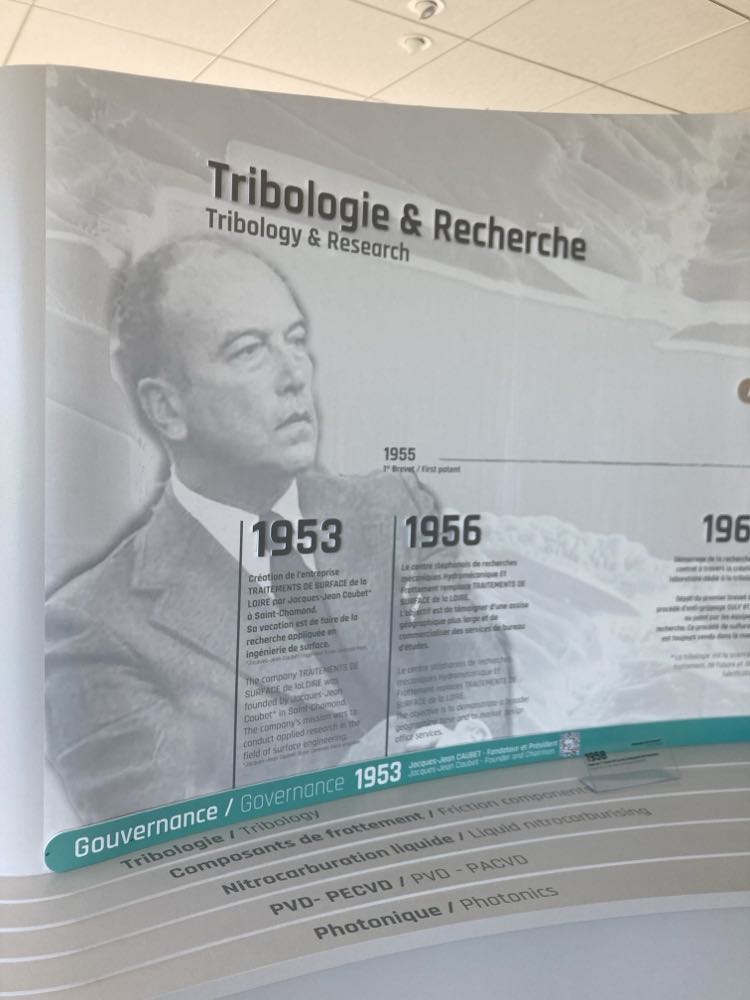

In fact, in 1953, Jacques-Jean Caubet, a graduate of the Ecole Centrale, founded the Centre Stéphanois de Recherches Mécaniques, Hydromécaniques et Frottements to solve the problems of premature wear on paper-making machines. This research center would later become the modern-day HEF Group.

Comprehensive tribological expertise

Tribology is concerned with an extremely large number of different situations where friction is involved.

HEF’s expertise in this sector focuses on different materials (metals, polymers, ceramics, etc.) and different lubricants (oils, greases, etc.) in operating conditions that are also quite different. For example, pressures ranging from "10–5 mbar to 35 bar, temperatures ranging from 200°C to +700°C, gaseous or liquid environments, and speeds up to several tens of m/s-1…

The following must also be taken into account: the geometry of the contact, the type of force applied, and also the surface properties present (hardness, roughness, chemical composition, geometric or structural defects, affinities with the lubricant, etc.).

All in all, there are more than a hundred parameters that may be involved in a tribology problem.

When a customer has a specific problem to solve, HEF can take a holistic view and propose a suitable solution, thanks to the expertise of our teams and our multi-scale digital and experimental resources.

Methodological focus

Our tribological activities often start with analysis of faulty parts that our customers will bring to us.

We then seek to understand the mechanisms of degradation in order to offer solutions that may mean modifications that impact the very design of the component or system in question, a change of materials, or use of surface treatments.

Thereafter, an experimental phase may be conducted to qualify and characterize the performance of the intended alternative solutions. For all these aspects, we have a variety of test methods as well as recognized experience in designing dedicated test benches should such a development be necessary.The objective of such experimentation is to replicate, as faithfully as possible, the operating conditions of the real application and identified degradation mechanisms.

Training courses are also offered for our customers’ teams (engineers, technicians, and materials experts) to explain the complexity of tribological issues, the consequences of these issues on components and systems, and the steps that must be taken to resolve these issues.