Friction components

Tribological expertise and friction components that ensure industrial performance. For more than 40 years, HEF has been developing and manufacturing a complete range of friction components that enable us to meet the most diverse needs of our customers. Two product ranges are designed and manufactured by HEF: – Key products, the “metallic components” are characterized by their use of specific treatments and adapted topographies, enabling high-accuracy guidance in extreme conditions (heavy loads, abrasion, impact, corrosion, etc.). – The “composite components”, our second product range experiencing rapid growth, are zero-maintenance, zero-lubrication products with low coefficients of friction, excellent wear resistance, load resistance, and reduced weight.

Contact our experts

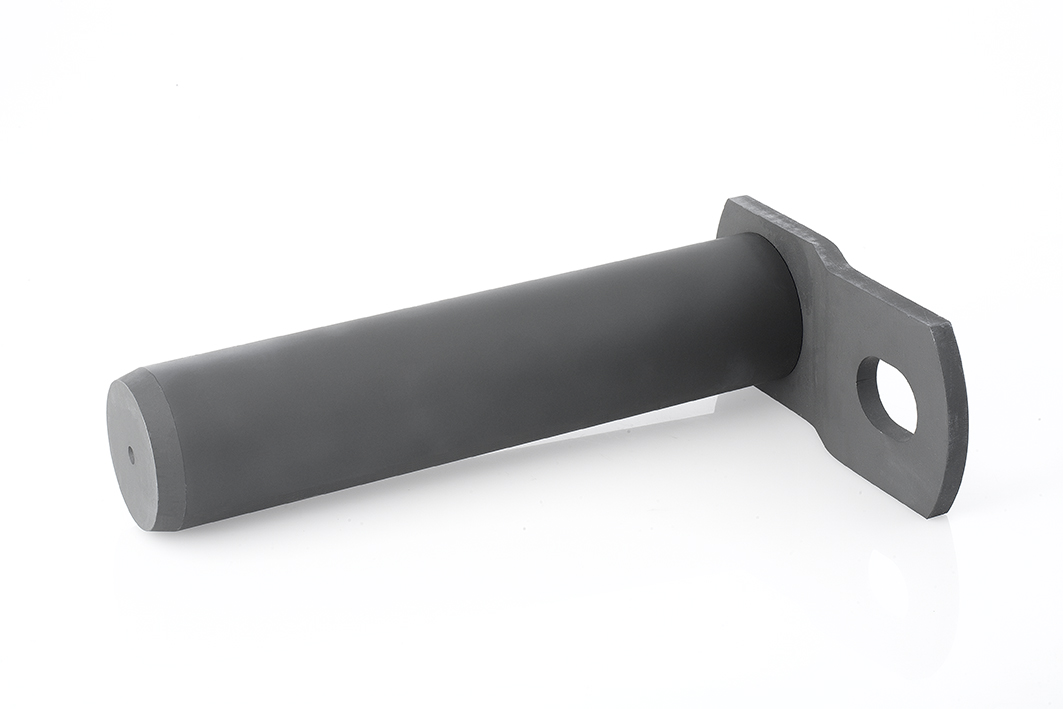

Metallic components range:

The metallic components developed by HEF are benchmark products in many sectors, such as civil engineering, agriculture, and the steel industry, to name a few.

The main range consists of PELTM products. These are machined bushings that offer excellent wear and seizure resistance, thanks to the combination of duplex treatment and a surface topography with special lubricant reservoirs.

They are used in difficult working conditions: high pressure, corrosion, abrasion, shocks.

With these bushings, service life and lubrication intervals are considerably increased, and guiding precision maintained over time.

They offer economic benefits, whether:

- Directly by replacing copper alloy bushings and/or through dimensional optimization (“downsizing”).

- Indirectly by reducing maintenance costs (simplification of lubrication systems, extended maintenance intervals).

The PEL® range is available in different technologies depending on the applications:

- Technologies with Pockets: PEL T, PEL BH, PEL BHR, PEL BH2, and PEL BH3 are dedicated to joints subjected to extreme pressures and requiring minimal lubrication.

- Technologies with cross-hatching: These are suitable for applications with automatic lubrication systems or subjected to low oscillations.

HEF also offers a range for applications in specific environments:

- High temperatures: TESCO range, up to 500°C.

- Maintenance-free, no lubrication in abrasive environments: Mangachoc and FAM ranges.

- Corrosive environments or steel industry applications: COD 11 range.

These technologies can also be adapted to other forms: shafts, sleeves, washers, slides, and ball joints…

Like friction bushings, these products result from many years of experience and testing conducted on the latest generation test benches.

Composite components range:

H-LinerTM is our range of composite components. These components offer resistance to moderate and heavy load, low coefficients of friction, and great protection against wear.

This material, which is available in several geometries, bushings, ball valves, rails, etc., also offers significant weight reduction compared to metal components, and this, in turn, facilitates and expedites installation and maintenance.

H-LinerTM M products are obtained by full-thickness filament winding of the friction material. They are fully machinable and are offered as flanged bushings, washers, plates or rails. For the most part, they are used for their low water absorption or accommodation capacity if there are alignment problems.

H-LinerTM S products consist of a friction layer wound on a glass-fiber based composite structure with high mechanical resistance.

These 2 families of products are also available in a version with integrated seals, referred to as the H-Liner® lip for applications exposed to abrasive environments.

H-LinerTM S1 products consist of a friction layer that is even more resistant to wear, on which is wound a glass-fiber, composite structure with high mechanical resistance.

Other components

HEF manufactures a wide range of customized parts, such as axles, spherical plain bearings and slides.

These components embody the technologies and know-how developed by HEF, and offer improved resistance to high loads, seizure, abrasion and corrosion.

The mechanical parts produced by HEF guarantee a longer service life, while reducing maintenance costs and ensuring optimal operation.

Developed recently for the same use conditions as the PELTM BH range, the PELTM IGO eliminates joint maintenance for the entire service life of the machine.

PELTM IGO works without lubrication in “high-pressure, high-speed” working conditions.

This innovation protects the environment by eliminating lubricant waste. It also eliminates lubrication-related maintenance tasks.

Advantages:

- No downtime

- Reduced lifecycle costs

- Significant maintenance reduction

- Increased guidance accuracy

- Operator convenience

- Eco-friendly innovation

Friction components and digital transformation

We combine digital technologies with our tribological expertise in order to reinvent the friction component and thus develop a solution for predictive maintenance for the joints on construction site equipment and infrastructure subjected to severe constraints.

PELTM4.0 innovation:

- Multi-level wear sensors

- Flexible dimensions; compatible with all types of machines

- Wireless communication

- No battery

- Weather-resistant

Our applications

HEF friction components are used in excavators, train braking systems, continuous casting ladles, cranes, dam floodgates, plows, and many other applications.

All this know-how is transferable to any other part that is subjected to friction forces.

Our range of friction components

The brands are:PELTM (PELLTM, PELLTM HP, PELLTM BH, etc.), MANGACHOCTM FAMTM, TESCOTM, COD11TM, and H-LINERTM (H-LINERTM S, H-LINERTM M, etc.).