Processes comparison

The main difference between both treatments is the physical medium used to allow nitriding: gaseous or liquid medium. Depending on the medium used, the process would be different, as synthesized in the following table:

Their respective processing methods – being quite different – are responsible for the unique effects each have on treated part.

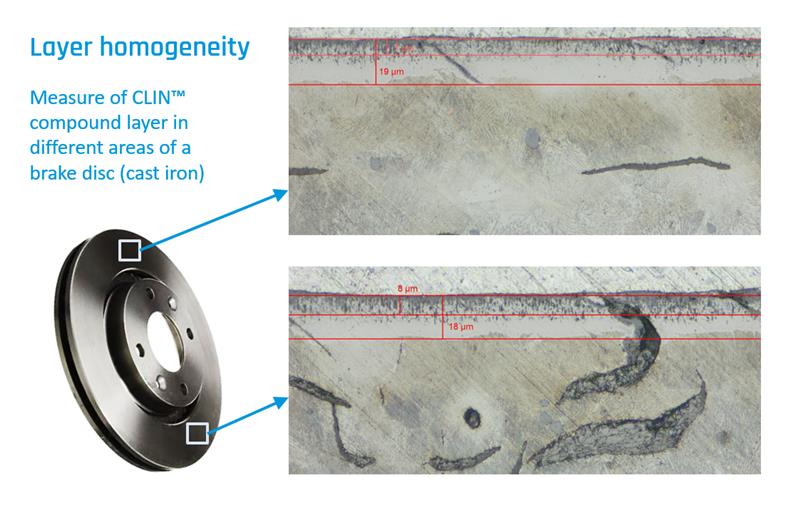

The temperature homogeneity control is quite different between gas nitriding and CLIN™ technologies. This is due to the difference of medium, rather than gas, CLIN™ is based on liquid medium (molten salts). Liquid allows a better control of temperature homogeneity compared to gas. Also, liquid enable complex geometry treatment, as it spreads uniformly everywhere in the bath.

This allows to have a better treatment homogeneity of the parts.

Parts are in direct contact with liquid and therefore use conduction for heat transfer. Gas uses convection which is not as efficient.

This efficiency is also bond with nitriding potential, directly linked to the chemical composition of the medium. Contrary to gas using Ammonia (NH3), CLIN™ technologies use cyanates (CNO–). These chemical compounds are more effective to create nitriding reactions, allowing fastest treatment times.

Thus, the liquid medium of CLIN™ offers the fastest and most uniform nitriding treatment.

| Gas nitriding | CLIN™ technologies | |

| Preparation | Degreasing with organic solvent | Degreasing: water + alkaline soap |

| Application method | Pressurized gas furnaces | Molten salt bath |

| Temperature range | 500 – 740°C | 500 – 630°C |

| Thermal uniformity | Env. ± 15°C | Env. ± 3°C |

| Heat transfer | Convection | Conduction |

| Nitriding potential |  Medium |  High |

| Treatment time | 6 hours – 24 hours | 1 hour – 3 hours |

| Environment/waste | The exhaust gases are cracked/burned/released into the atmosphere. | Recycling of line waste into new consumables directly usable. |

| Toxicity classification | Ammonia (anhydrous) | Cyanates and carbonates |

Advantages and limitations of CLIN™ compared to gas

Advantages:

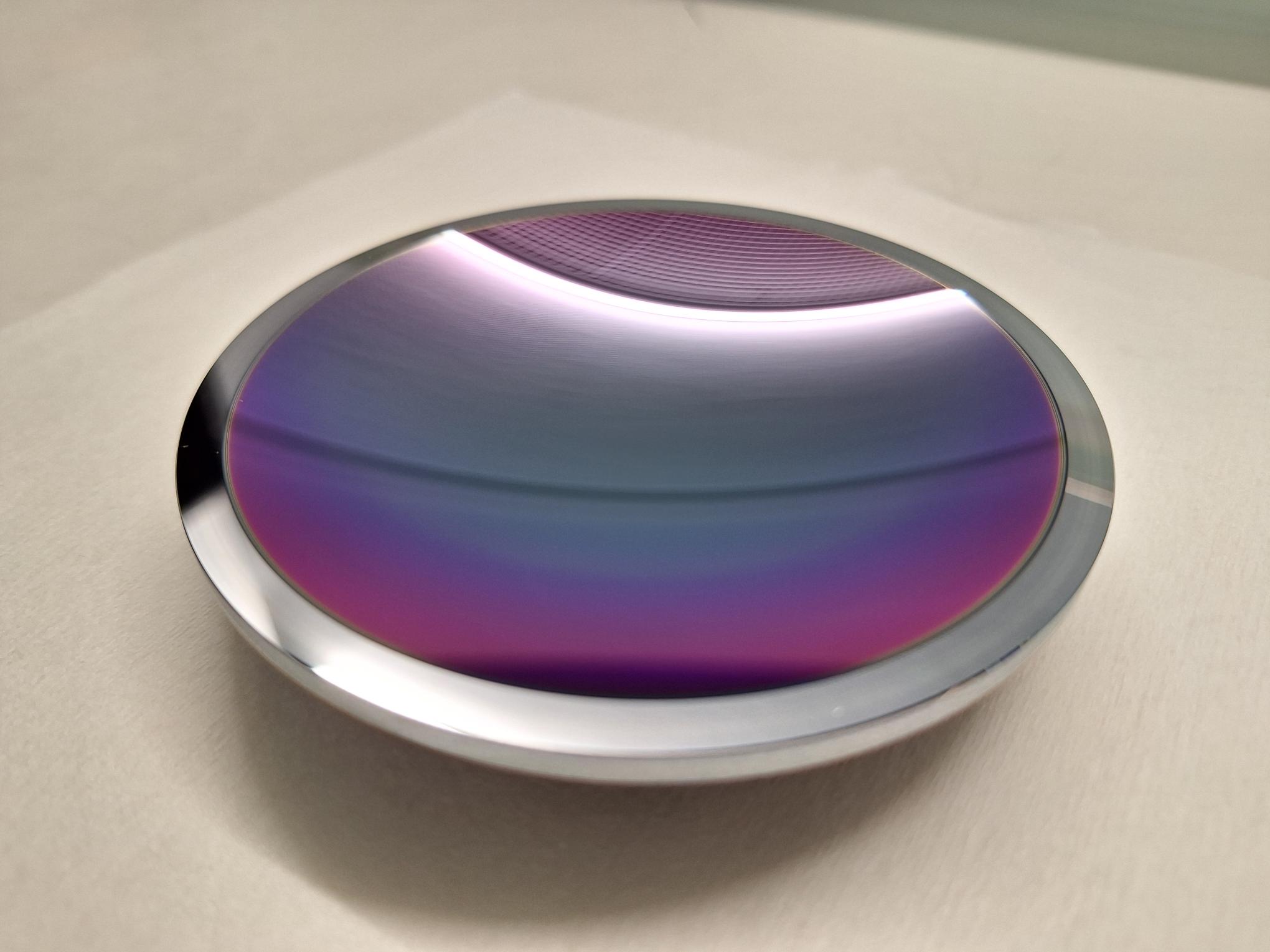

- Uniform compound layer thickness even on parts with complex geometry.

- Better dimensional control on the parts.

- Minimal to no-distortion on parts.

- Better adhesive wear resistance, due to post-nitriding enhanced oxidizing step.

- Better oil retention.

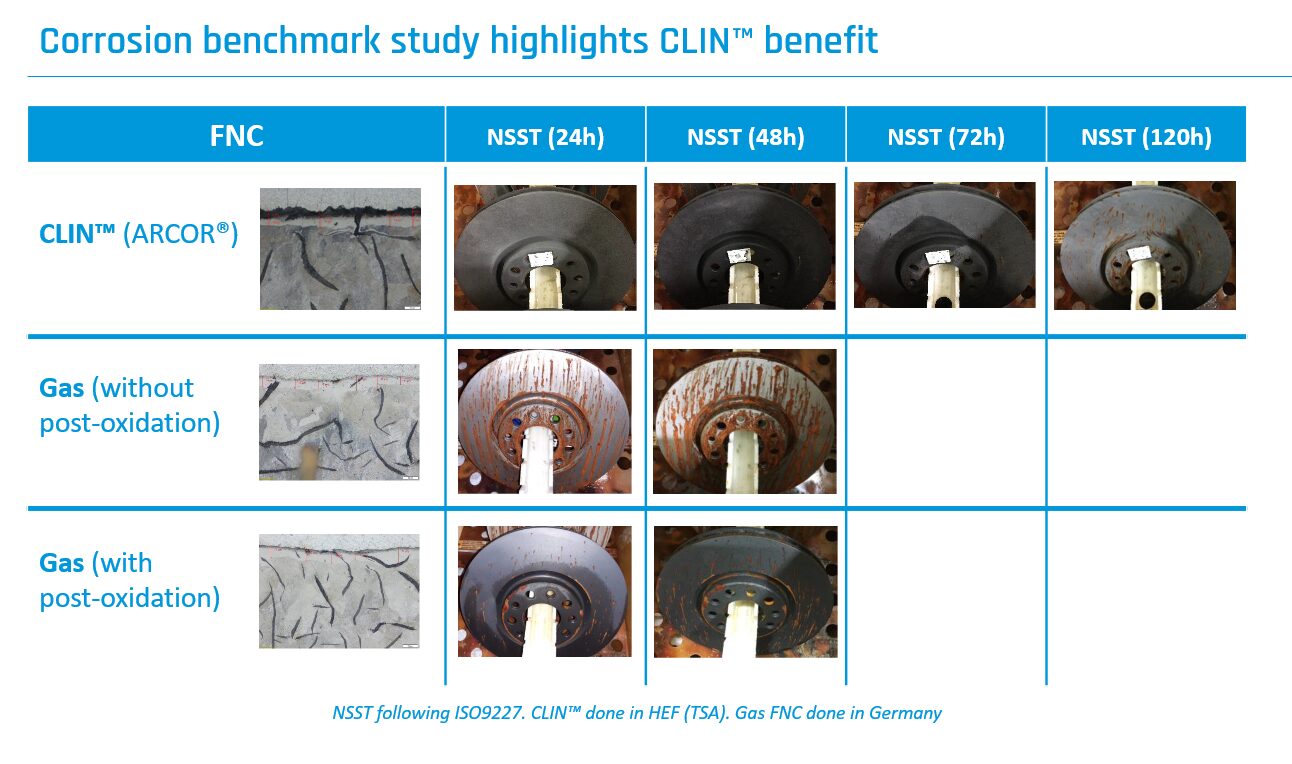

- Enhanced corrosion resistance.

Limitations:

- Masking is most of the time not possible.

- Less deep nitrogen diffusion.

From an economic perspective, both processes, gas or liquid, are competitive technology well known in various industries as construction, handling, automotive, energy, aeronautics and defence.

Availability of CLIN™ technologies

CLIN™ is globally available with TUFFTRIDE®, TENIFER® & QPQ® treatments licensed to subcontract heat treatment trade. ARCOR® and SURSULF® are version of CLIN™ commercially available throughout our global TS network.

Regarding environment and wastes, ECO-CLIN™ innovation process is allowing a circular model by recycling, into new consumables directly usable on CLIN™ line. As a first step, most of Europe lines’ wastes are recycled by this time; the ambition of the group is to achieve zero final waste within its worldwide network.